Home » Safety Shoes » Direct Moulding of Soles

Direct Moulding of Soles

Description

Stemma is specialized in designing and manufacturing polyurethane processing machines and since 20 years is committed to the development of technologies and systems for the footwear industry.

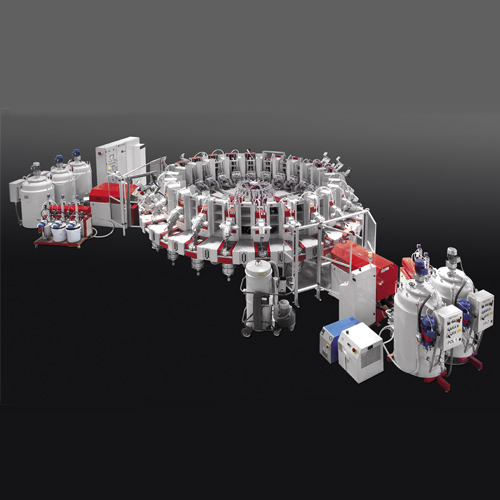

Automatic rotary machine 18/24/30 stations for direct molding of PUPU and TPU/PU soles.

Maxima 13, the third generation of the successful Stemma's machine represents a real step forward in the footwear technology.

Maxima 13 is available in 3 versions :

- Maxima 13S : for direct molding of single-layer PU soles

- Maxima 13B : for direct molding of double-layers PU-PU soles

- Maxima 13T : for direct molding of double-layers TPU-PU soles

This new generation of low-pressure self-cleaning unit for injecting polyurethane, benefits of the innovative "Hydrodynamic Drive" to control the opening and closing of the Polyol and Isocyanate injection valves.

With this advanced "hydrodynamic valve-action system" the "injection pin" is moved by pressure of over 100 bar that ensures a very fast opening of the valves when the machine halts for shorts or long stops and guarantees that movements are synchronized to avoid all possible "pre-run fenomena". A new shutter system guarantees the perfect closing of the recirculation valve. The use of this innovative technology guarantees maximum functional stability while, at the same time, maintaining the versatility of the fully independent valves system especially suited to multi-polyol injection groups in which one isocyanate circuit and two or more polyol circuits can be installed.